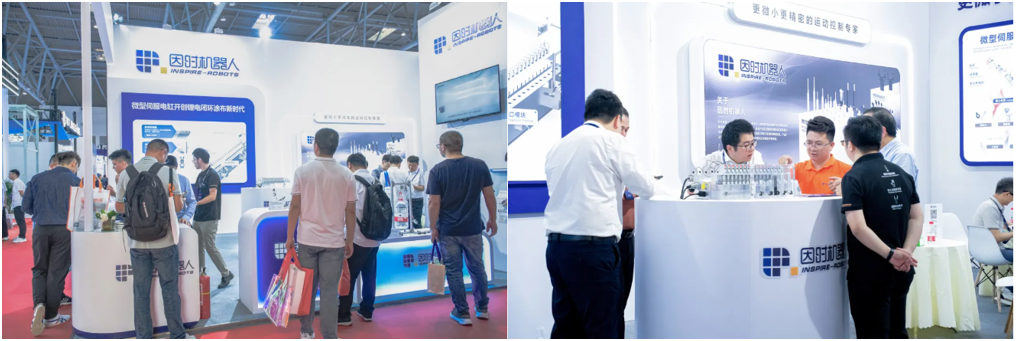

China International Battery Fair (CIBF) is one of the most influential new energy exhibitions in the world, showing the strength of new energy enterprises, the latest technology, scientific research achievements …… for the global new energy industry provides a strong impetus.

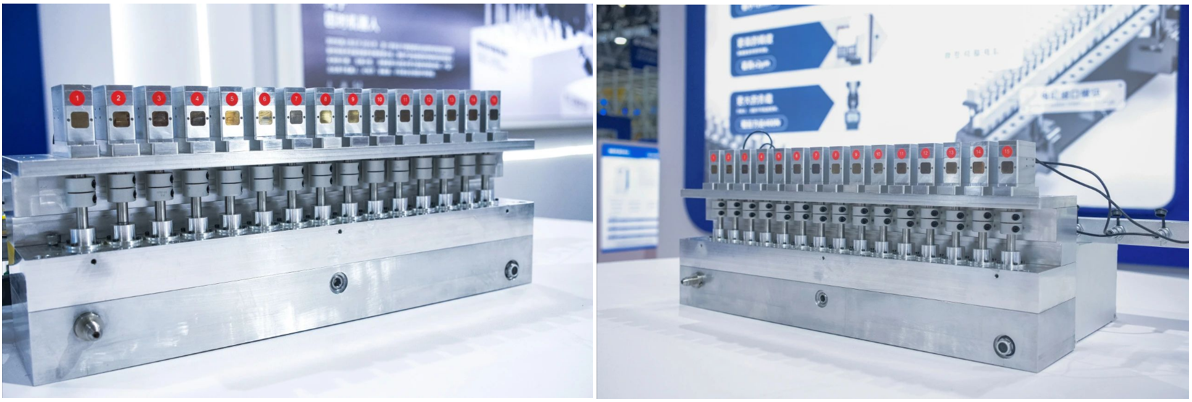

From April 27th to 29th, as a core robot parts company, INSPIRE-ROBOTS brought its full series of Micro Linear Servo Actuator and its application case in the li-ion battery industry – intelligent closed-loop coating die head to the exhibition, which triggered the attention of the whole audience. INSPIRE-ROBOTS innovatively applied the Micro Linear Servo Actuator to the closed-loop coating die head of the core equipment for li-ion battery production, and took the lead in assisting the industry to carry out the transformation of the closed-loop die head by configuring a Micro Linear Servo Actuator for each adjusting slider within the spacing of more than 1cm of the coating die head, thus realizing the full-automatic adjusting of the coating die head. After the modification, the COV value of the closed-loop coating die head has been greatly reduced, and the A-rate of the battery has been increased, which has brought great economic benefits to the terminal battery factories.

As the pioneer of Micro Linear Servo Actuator, the narrowest pitch of the actuator of INSPIRE-ROBOTS can be 12mm, and the precision can reach ±2μm, which is the only one that INSPIRE-ROBOTS can achieve in the world.

Micro Linear Servo Actuator helps battery industry to reduce cost and increase efficiency

Coating machine is the core equipment for li-ion battery production, and its function is to uniformly apply slurry on the substrate through the slit-type coating die head to make positive and negative electrode wafers. The traditional slit coating die head slider spacing is only 1 cm or so, and can only be adjusted manually by micrometer, the real-time and adjustment accuracy of the coating is difficult to be guaranteed, which directly leads to the low A-rate of the battery and low production efficiency.

The introduction of Micro Linear Servo Actuator has brought a ray of hope for the automation transformation of slit-type coating die head!

In the coating die head more than 1 cm spacing for each adjusting slider configuration of a Micro Linear Servo Actuator, the coating die head to achieve fully automatic adjustment, to solve the problem of adjustment lag, on-line production after the production rate and production efficiency and yields increased dramatically, the ROI effect is immediately visible.

In this year’s CIBF, thanks to the small size, high precision and large load of the miniature servo cylinder, many engineers from the battery industry were attracted to the booth of INSPIRE-ROBOTS for consultation. In addition to the closed-loop coating die head, there is still a lot of application space in other equipment and process links of battery production and manufacturing.

The Dexterous Hands promotes the landing of intelligent factory

As the first domestic company to commercialize and mass produce The Dexterous Hands, INSPIRE-ROBOTS has broken through a number of technological bottlenecks to significantly reduce the cost of dexterous hand. In the current situation of rapid development of body intelligence, The Dexterous Hands can help many terminal factories to realize human substitution in some basic operation links, to further improve the efficiency of factories, and become a key help to promote the landing of intelligent factories.

With the continuous updating of lithium technology, iterative, lithium production equipment in all aspects of technology upgrades to better meet the requirements of manufacturers of high consistency and high stability of products. Micro Linear Servo Actuator as the core components of the robot in the lithium industry’s innovative applications not only help the new energy industry to reduce costs and increase efficiency, but also proved once again that robotics in the field of intelligent manufacturing will have a greater role.

In the future, INSPIRE-ROBOTS will be based on the core technologies of micro-small size, high precision and force control, injecting new power for realizing more precise intelligent and automated control, and accelerating the factory to realize flexible production and intelligent manufacturing.