All theories and factories can’t be realized without equipment, and the efficiency of the equipment is crucial.

Coating machines are the core equipment in lithium battery production. Their function is to evenly apply the slurry onto the surface of copper or aluminum foil through a slot coating die, forming the positive and negative electrode sheets. The uniformity and consistency of the coating directly determine the performance and lifespan of the final battery, while the coating speed affects the production capacity . Traditional slot coating dies, however, are limited by the small adjustability of the slider spacing, requiring manual adjustment, which has become a bottleneck that restricts the advancement of battery production.

Micro Linear Servo Actuator Bring Significant Transformation to the Coating Industry!

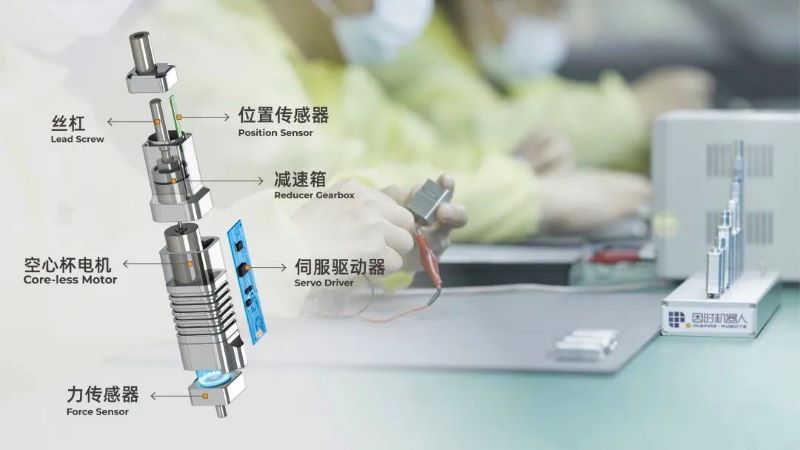

Micro Linear Servo Actuator is a small integrated linear servo system, which is the core motion component of precision electromechanical equipment such as robots, medical equipment, industrial equipment and so on. Micro Linear Servo Actuator integrates a core-less motor, a precision planetary reducer, a sensor, a precision screw mechanism and a closed-loop control system, achieving integrated drive and control with a smaller form factor, with a small size, high precision, large load and other technical characteristics.

In the past, traditional slot coating dies had a minimum slider spacing of just over 1 cm, which could only be adjusted manually using a micrometer. Workers had to continuously monitor the coating data from the thickness gauge 24/7 and make corresponding adjustments, leading to frequent changes. As a result, real-time coating accuracy and adjustment precision were difficult to ensure, which directly led to long-standing issues such as low battery yield, low production efficiency, and high staffing requirements.

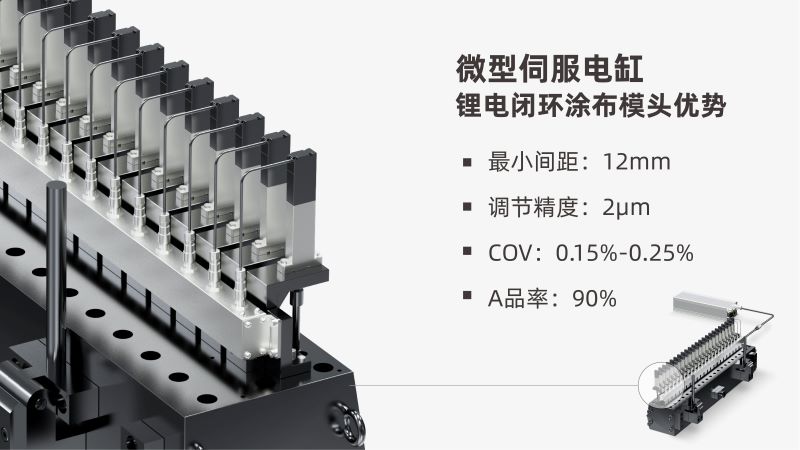

Micro Linear Servo Actuator are innovatively applied to the coating die, with one micro servo actuator configured for each adjustment slider within the 1 cm spacing of the coating die. This enables fully automated adjustment of the coating die, solving the problem of adjustment delays. Not only does this enhance production capacity, but it also improves the battery yield rate (A-grade rate).

Intelligent Closed-Loop Coating Die Make Battery Production More Efficient

INSPIRE-ROBOTS’ micro linear servo actuator can achieve a minimum spacing of 12 mm, with precision reaching ±2 μm and a push-pull force of up to 40 kg.

Such performance can only be achieved by INSPIRE-ROBOTS in the world. After the coating die is upgraded with micro linear servo actuator,the COV value can be reduced to 0.15%, and the A-grade yield rate can reach 90%, which brings great economic benefits to the terminal battery manufacturers.

The new energy industry has long struggled with the drawbacks of lithium battery coating equipment. In 2022, INSPIRE ROBOTS took the lead in assisting top industry clients with closed-loop die upgrades. After going into production, both production efficiency and yield rates were significantly improved, with an immediate and impressive ROI effect.As the pioneer of Micro Linear Servo Actuator, INSPIRE-ROBOTS, with an annual output of over 10,000 units, high quality, strong stability, and fast delivery, has become the preferred choice for many new energy manufacturers and equipment suppliers for upgrading and manufacturing of closed-loop dies.

INSPIRE-ROBOTS has almost stablished partnerships with the top 10 battery manufacturers.The diversity, maturity, and reliability of Micro Linear Servo Actuator have been fully validated by the market, with hundreds of closed-loop coating dies were put into production in 2023 alone.

Rich experience & mature products become the first choice in the coating market

Thanks to years of in-depth service in the coating industry, INSPIRE-ROBOTS has a wider range of electric actuator for coating. The full product suite includes Micro Linear Servo Actuator, interface module and main control unit, capable of meeting different pin count requirements, with complete products available for 20, 60, 80 pins and more.. The micro servo actuator is the executing device, with each actuator connected to an interface module on the back.The interface module transmits a bus cable to the main control unit. The main control unit runs the closed-loop algorithm and communicates over the network to control the execution of all the micro servo actuators.

Currently, INSPIRE-ROBOTS offers five standard series of micro servo actuators with a wide range of products to meet the various spacing requirements of coating dies, from narrow to wide. These products cover over 90% of coating machine upgrades, ushering a new era of lithium closed-loop coating.

As the pioneer of micro linear servo actuators, INSPIRE-ROBOTS’ innovative R&D team comes from institutions such as Beihang University’s Robotics Research Institute, Shanghai Jiao Tong University, and Beijing University of Science and Technology. With over ten years of experience in robotics technology development and product innovation, the company has served thousands of clients to date. It is reported that micro servo actuators on new energy battery production lines not only facilitate the upgrade of coating dies but also meet various needs in other process stages. In the future, INSPIRE-ROBOTS will continue to focus on core technologies such as miniaturization, high precision, and force control, injecting new momentum into achieving more precise intelligent automation and accelerating flexible production and smart manufacturing in factories.