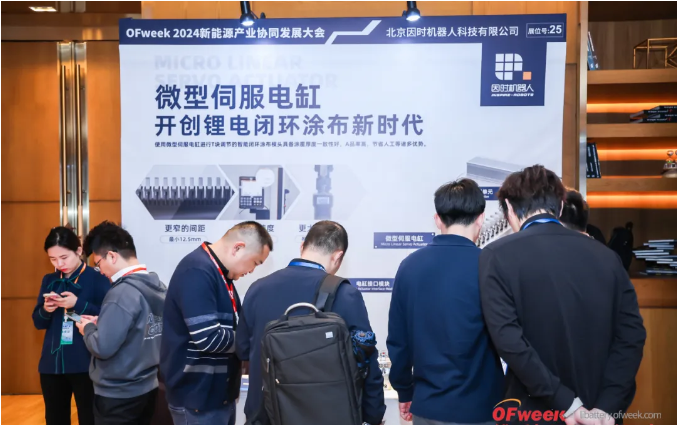

On March 19, 2024, “OFweek 2024 New Energy Industry Synergy Development Conference” kicked off at Hyatt Regency Shenzhen Airport, with more than 500 famous enterprises and more than 2,000 people participating in the conference. As the introduction of the conference said, the development of new energy is not to fight alone, but innovation, integration and win-win situation will run through the new energy industry chain. As a core robot components enterprise, INSPIRE-ROBOTS has innovatively applied Micro Linear Servo Actuator to li-ion battery production equipment, which not only greatly improves the quality of batteries, but also assists battery factories in realizing cost reductions and efficiency gains. In this new energy industry conference, INSPIRE-ROBOTS exhibited the application of Micro Linear Servo Actuator in li-ion battery industry – intelligent closed-loop coating die head demonstration tooling.

Coating die head is the new energy industry li-ion battery production of the core equipment, because the slurry ductility is very low, how to ensure consistent and uniform coating it. Through the coating machine die head slurry extrusion of more than a meter lip are divided into dozens of individual control areas, with a T-bar slider to control the transverse areas of the local flow control, and then guarantee the consistency of the coating thickness of the slurry at the exit. The narrowest slider spacing is only 1 cm, there is almost no such small actuator on the market, such as electric cylinder adjustment, can only be adjusted manually using a micrometer, which also leads to a low rate of A battery, the staffing requirements of the higher requirements and low production efficiency and other problems are difficult to solve.

The Micro Linear Servo Actuator is small in size, high in precision and large in load, and it can be configured with a Micro Linear Servo Actuator for each adjusting slider within a spacing of more than 1cm of the coating die head, realizing fully automatic adjustment of the coating die head, solving the problem of adjustment lag, and improving the production capacity as well as the A-rate of the battery.

Micro Linear Servo Actuator creatively upgraded the core equipment for li-ion battery production in the new energy industry to intelligent closed-loop control, and the transformed closed-loop coating die head has many advantages such as real-time deviation correction, real-time control, good uniformity and high production efficiency. This will inject a new impetus for the development of new energy industry and promote the progress of the whole industry.

In OFweek2024 (8th) power battery industry annual meeting “battery manufacturing”, around the battery production how to improve the quality of the theme of cost reduction, many industry experts to offer advice. In the special forum, Ms. Hainan Fang, Marketing Director of INSPIRE-ROBOTS, also delivered a speech on the theme of “Micro Linear Servo Actuator to help li-ion production automation and intelligence”.

Around how to apply robotics to the li-ion industry, Micro Linear Servo Actuator has what advantages, and how to play a role in many industries and other content to carry out a detailed and in-depth explanation.

In the round-table dialog, the moderator raised the question of “how to further improve the yield of battery products”. Ms. Fannanai said: the first to improve the performance of production equipment, like Micro Linear Servo Actuator in the closed-loop coating die application , through the intelligent transformation of the equipment, to achieve the automation of the production process, improve the yield while also improving production efficiency; the second is to reduce the human factor, a lot of production is still heavily reliant on manpower, human operation is not controllable leading to a decline in yield, in the current situation of with the rapid development of the body intelligence, to help large-scale production of batteries and battery products, to improve the yield, and to improve the efficiency of production. In the current situation of rapid development of body intelligence, to assist large terminal factories in some basic links to realize the dexterous hands manpower substitution work, I believe it can also help to further improve the product yield rate.

As the pioneer of Micro Linear Servo Actuator, the narrowest pitch of the actuator of INSPIRE-ROBOTS can be 12mm, the precision can reach ±2μm, and the thrust and pull force can reach 40kg. Such performance can only be achieved by INSPIRE-ROBOTS in the world. The COV value of the coated die head can be reduced to 0.15% and the A-rate can reach 90% after the transformation of the Micro Linear Servo Actuator, which will bring great economic benefits to the terminal battery factory.

With the continuous updating of li-ion technology, iterative, li-ion production equipment in all aspects of technology upgrades to better meet the requirements of manufacturers of high consistency and high stability of products. Micro Linear Servo Actuator as the core components of the robot in the li-ion industry innovative applications not only help the new energy industry to reduce costs and increase efficiency, but also proved once again that robotics in the field of intelligent manufacturing will have a greater role.